Simplified pipe support speeds-up laying head pipe change

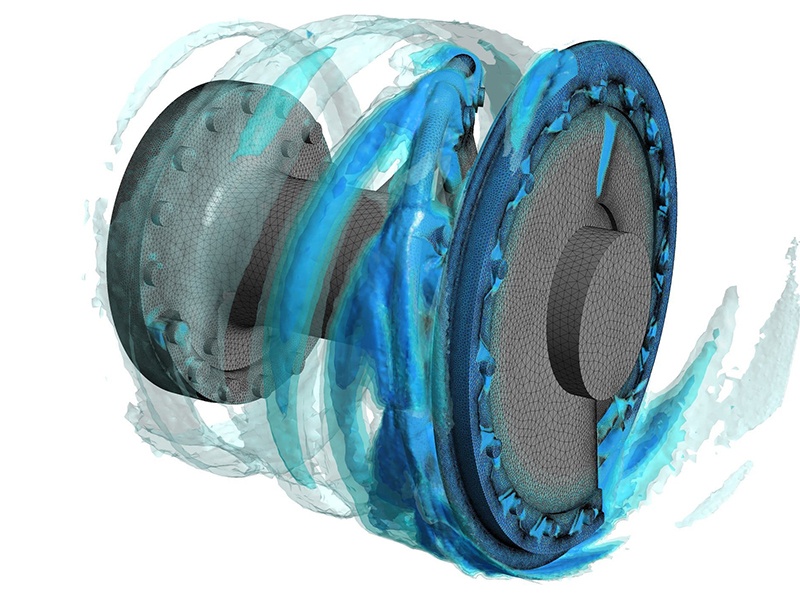

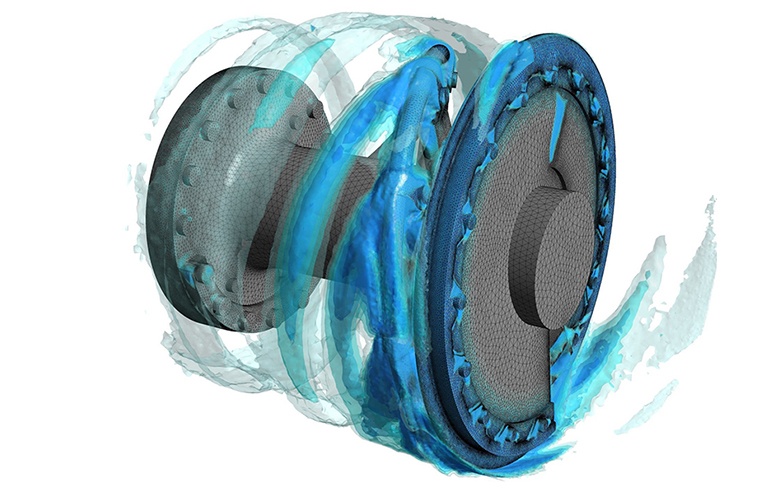

In today’s rolling environment of intense speeds, the production of small diameter wire rod can burn up the laying head pipe and require periodic replacement. The question is not if, but when, and a reality that many wire rod producers must address during every rolling campaign. No one wants to stop production to change out the laying head pipe.

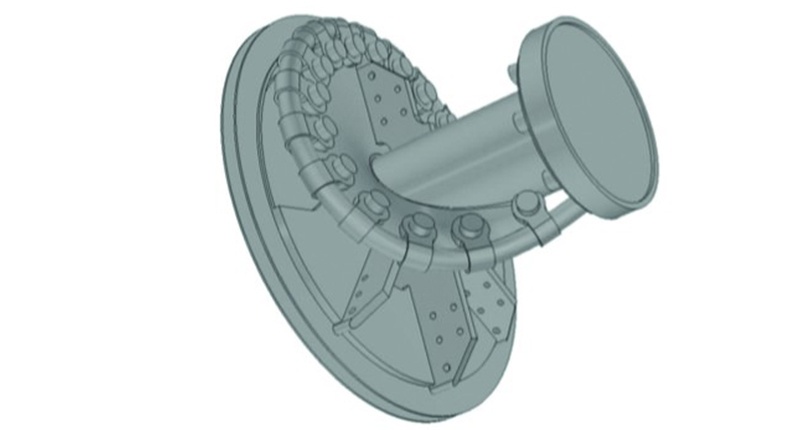

Typically, laying head pipes have 14 clamps. Russula has redesigned the pipe support and reduced the number of clamps to 9, without reducing product integrity, functionality or durability. Now mill operators can change the laying head pipe easily and in less time.

Difficult access to the laying head pipe increases production downtime. Current laying head designs require the removal of multiple segment plates, most have an average of five plates, or ten separate pieces, which need to be removed in order to access and change the burned out pipe. Russula has simplified the process by reducing the number of plates to four pieces that require replacement, thus making it much easier for the mill operators to access the pipe and change it out in record time.

Standard laying head pipe change-out time: 30-45 minutes

Russula laying head pipe change-out time: 15-30 minutes

Russula's simplified laying head pipe change process eliminates 36% of the clamps used on standard technology, which reduces the change out time by half. Here are the main benefits to the patented laying head design.