Revamped motor orientation streamlines maintenance

Russula has redesigned the motor configuration of its latest laying head technology, allowing for tighter tolerances to be used in the labyrinth seal design, which keeps oil from escaping and causing environmental problems. All of this is possible because the axial alignment and positioning of the quill are greatly improved in this new system.

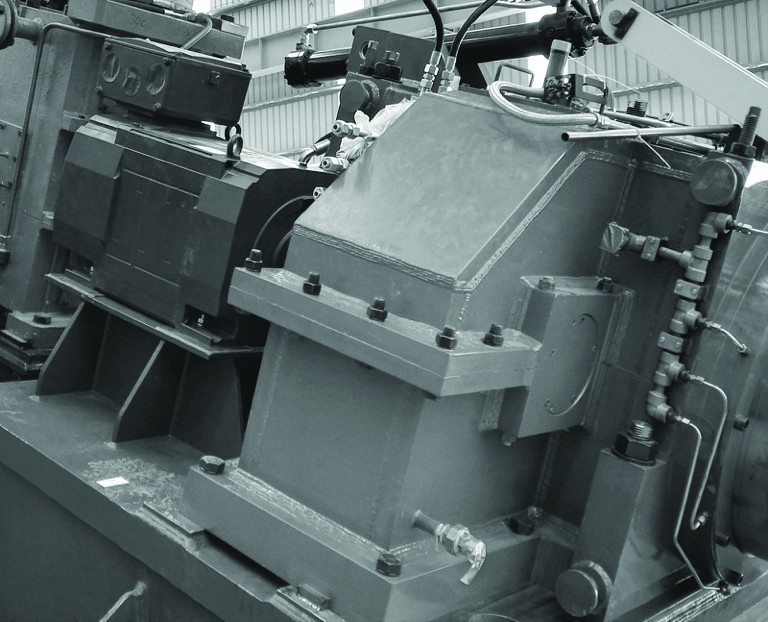

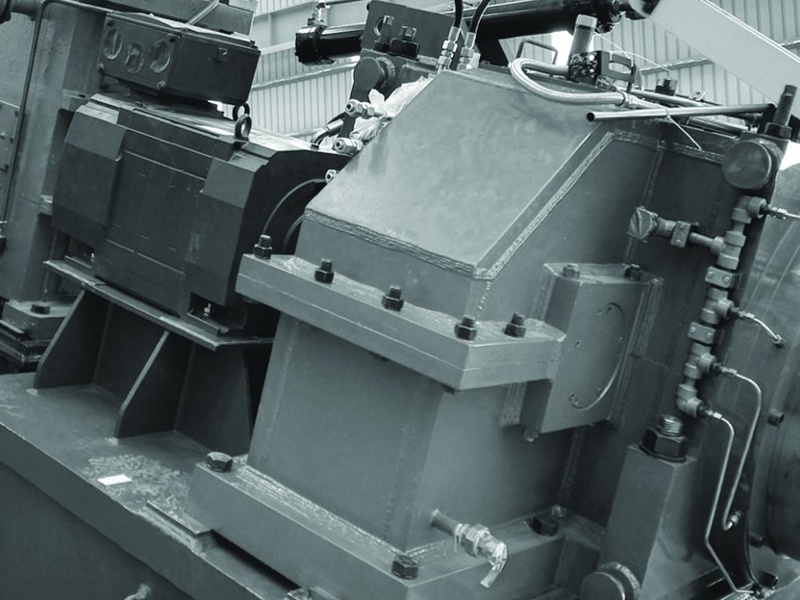

In the current Russula design, the centerline of the motor is parallel to the centerline of the laying head, as shown in the photo below. It sits on the same integrated base as the laying head itself, which creates a more compact, stable footprint. Because of this configuration, expensive spiral bevel gears in a typical laying head are eliminated; they are replaced with more affordable, helical gear sets.

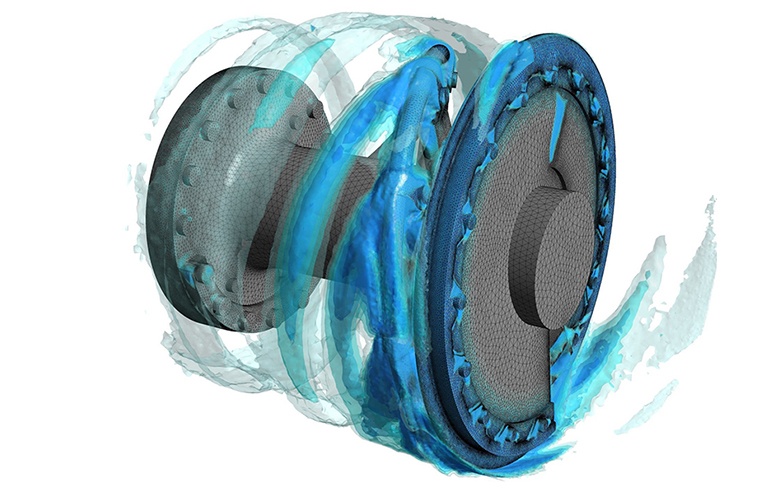

The axial alignment, using helical gears, also better positions the quill inside the assembly to a tighter specification and this enhanced positioning of the quill determines how the oil flows through the labyrinth. In Russula’s new design, the static and rotary portion of the labyrinth seal is positioned very close to each other, which makes it harder for oil to travel through the labyrinth and helps prevents oil leakage.