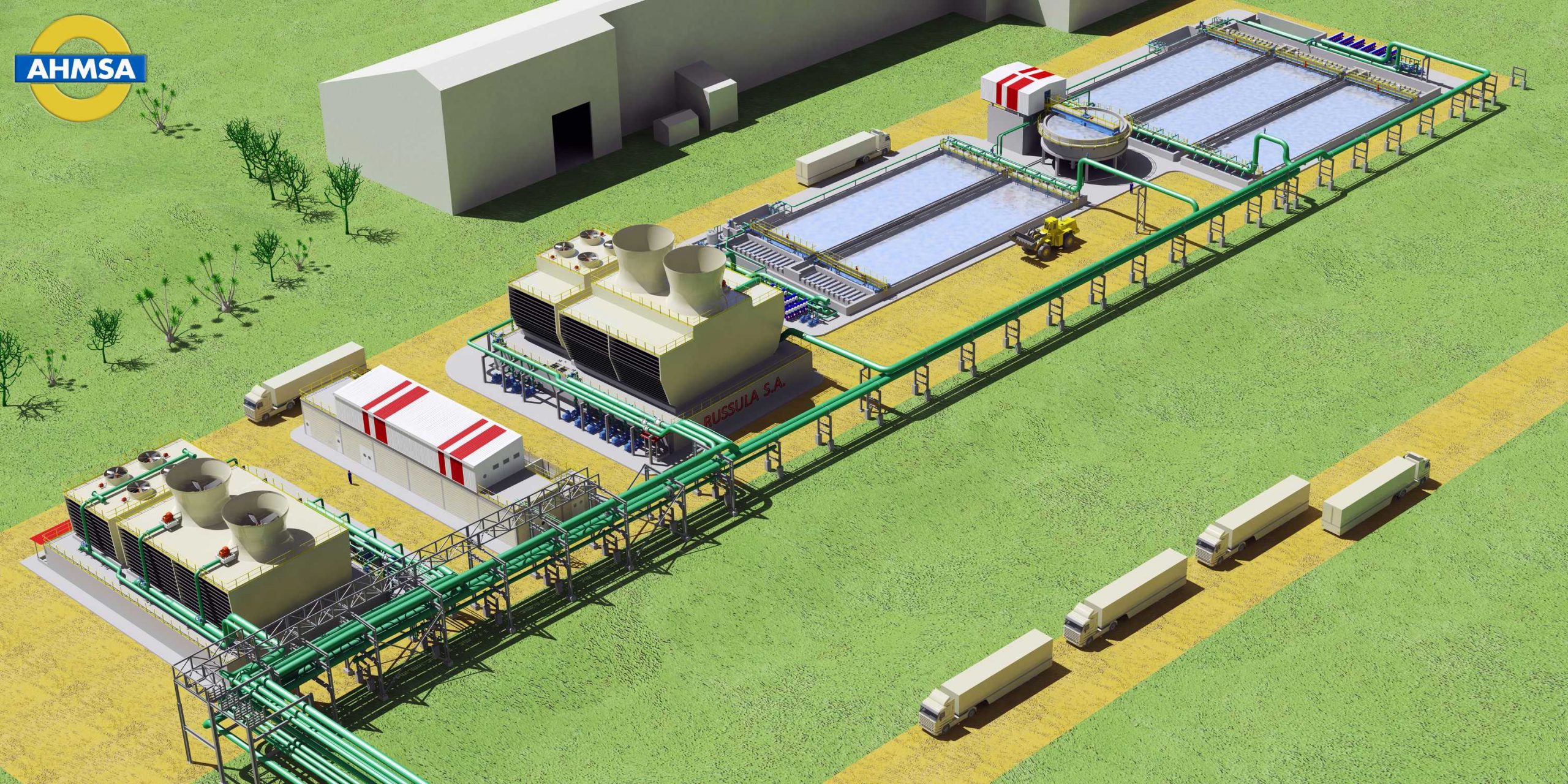

Water treatment plant for Steckel Mill

Russula was selected for the turn-key supply of the water plant for the new 1 Mt/yr Steckel plate mill at AHMSA. The new green field water treatment plant has a capacity of 7,400 m³/hr (32,700 gpm) for the contact water circuit and 4,600 m³/h (20.300 gpm) for the non-contact water circuit. Russula supplied all the basic and detailed engineering, as well as all the mechanical and electrical equipment, including all the prefabricated piping. Russula also supervised all the civil works, mechanical and electrical installation for the whole project.

Technology

The main equipment is designed around Russula's twin decanting concept, complete with ring filtration and field erected cooling towers. The recirculating water system is designed to meet stringent water quality requirements including total suspended solids, PH and temperature. The engineering developed in 3D integrated civil works, piping, supports and equipment to optimize installation work and minimize assembly time.

Project Execution

Russula provided 310 tons of piping and 80 tons of prefabricated metal structures. The installation of prefabricated piping minimized welding during assembly and surplus materials, streamlining the project implementation.

"The entire water treatment plant was constructed in one year from breaking ground to final installation."

The construction of the water treatment plant consisted of 27,500 m³ of excavation work, 6,600 m³ of concrete, 16,000 m² of form work, 515 tons of reinforcing steel, 58 tons of embedded metal, 15 miles of electrical metallic conduits and over 23,000 items of hardware were used during construction.

Project Layout

The water treatment system for the new Steckel mill consists of four circuits:

Results

The Steckel mill and water treatment plant started-up in the fall of 2013. The water treatment plant has met and exceeded AHMSA's stringent water requirements. This design incorporates ring filters that can endure oil spillages that would have ruined other kind of filters, an ideal solution for this kind of application. Russula's water treatment solutions are proven technologies that maximize efficiency, while minimizing used space.