Big River Steel Water Treatment Plant Phase I

In April 2015, Big River Steel (BRS), located in Osceola, Arkansas awarded Russula the contract to supply a Water Treatment Plant (WTP) for the world’s first Flex Mill integrating a meltshop, hot strip mill and cold mill together. In the first phase of construction, the plant produced 1.5 Mtpy of hot rolled strip, which was processed directly into cold rolled strip and hot-dip galvanized sheet. At a later stage, a second CSP® (Compact Steel Production) caster was added, which increased the capacity to 3 Mtpy. Approximately a third of the manufactured products were sold directly as different grades of hot strip and the remaining amount was processed in the pickling line, which was coupled with the five-stand tandem rolling mill.

35,000 m3/hr Water Treatment Plant

The meltshop has a 150 ton EAF, a 150 ton ladle furnace with two treatment stations and a RH degasser. It is equipped with a gas cleaning plant to ensure compliance with the environmental standards in place. Nine hundred thousand tons of pickled hot strip are rolled in the tandem mill. The coupled pickling line/tandem cold mill are equipped with a laser welding machine, a descaler and a turbulence pickling section. Approximately half of the cold rolled strip is processed in the continuous galvanizing line and the other half in the batch annealing furnace.

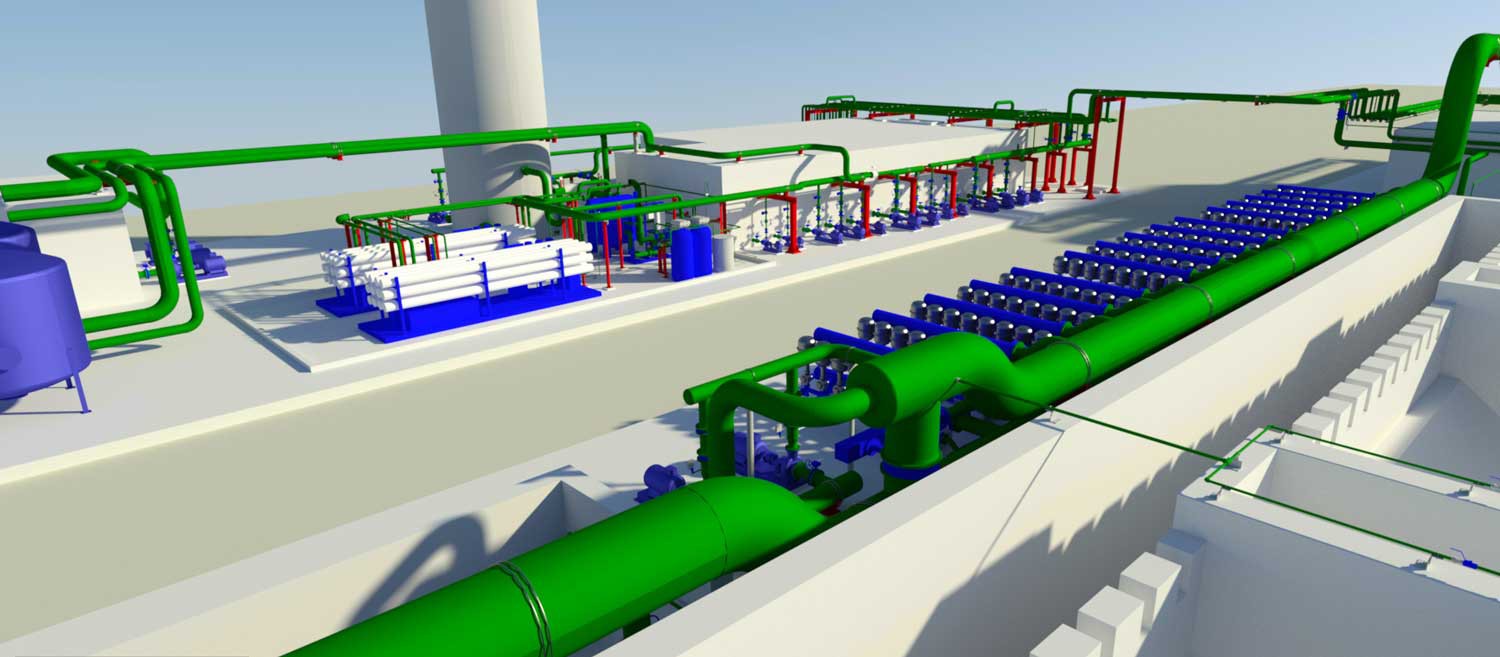

The water system treats and supplies 35,000 m3/hr of water for all these systems, as well as the make-up water system, which treats the water originating from several deep wells, a purging system and the waste treatment of the cold emulsions mill. The water treatment plant has been designed to reduce fresh water requirements, to keep operational costs under control such as energy consumption and to facilitate maintenance operations.

The water treatment plant is divided into four areas:

- Melt shop Area

- HSM & CCM Area

- Laminar Area

- Cold Mill Area

Each area is, by all means, a water treament plant in itself, built close to the processing area of the water it treats, which reduced the cost of having to fabricate and erect extensive piping.

Pretreatment zone and HSM ring filters

Engineering

The complete engineering of the water treatment plant, from the civil engineering to the piping, mechanical engineering and electrical engineering was included within the scope of supply. The engineering development in 3D for the piping, supports and civil work, added tremendous value to this project, as it optimized the installation work, reduced delays with the electrical work and minimized installation time, a point of major importance during the water treatment plant construction.

Mechanical Equipment

All of the mechanical equipment selected for this project were recognized brands, keeping quality and reliability always as the main driver. The main equipment at a glance:

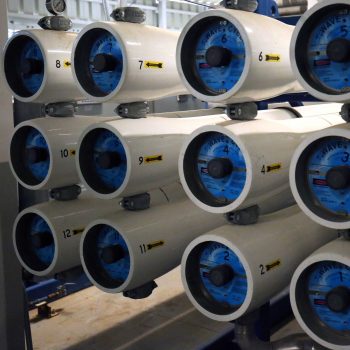

Furthermore, the complete mechanical supply included valves, bridge scrapers, plate heat exchangers, an oil skimmer, a sludge thickener, filter press, as well as softening, reverse osmosis, sand filtration and an aeration system.

Electrical Equipment

The water plant will has an installed capacity of 22 MW.

Installation Materials

Services

Highly skilled Russula supervisors, specialized in civil, mechanical and electrical engineering, assisted Big River Steel in transforming the engineering diagrams into fast construction. Together with the Big River team, Russula commissioned the water treatment plant. Engineers remained on-site until the steel processes reached normal, consistent operation. During this time training was administered to the Big River staff.

Timing

Russula designed, supplied and commissioned the water treatment plant within 14 months from the award date. The engineering developed in 3D for the civil works and piping, together with the supply of prefabricated piping were key aspects to delivering a speedy implementation. Eighty containers were be sent from Spain, Germany, Sweden, Italy and the United States. The mix of equipment suppliers from Europe and the United States helped to shorten the delivery times.

During the second quarter of 2016 the on-site construction and installation was executed in preparation for the start-up. Specialized personnel from Russula were on-site throughout the WTP construction to ensure correct equipment installation as well as to minimize human error. Good communication and teamwork between the Russula specialists, BRS and subcontractors were crucial to delivering this project in time for the start-up of the Flex Mill.