Steady and ready to roll | Mill Setup

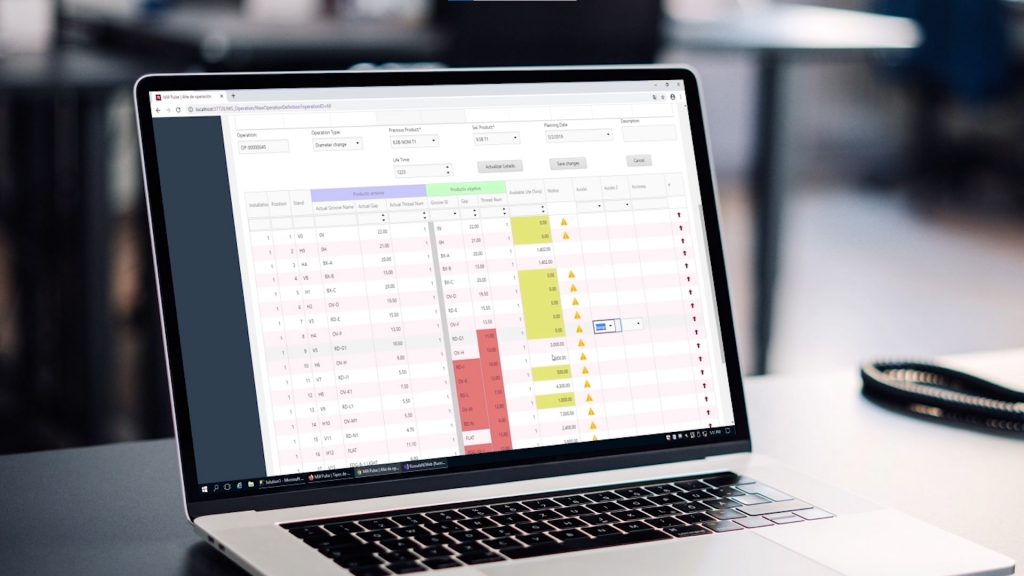

Leveraging 30+ years of knowhow and experience, Russula designed Mill Pulse® exclusively for rolling mills. Minimizing costs, time and effort is at the forefront of the Mill Setup module. This module enables and facilitates all tasks related to the mill equipment setup in the plant layout by integrating the rolling process and roll shop together.

Mill Setup represents an important leap compared to the traditional MES system, managing the life cycle of equipment and consumables from the workshop to the Mill and their return to the workshop, handling the equipment necessary to roll each defined product and generating check lists per each product change stop. While the rolling mill is in operation, Mill Pulse® monitors tons and time of use for each piece of equipment and collects information from workshop tasks, like equipment status, remaining wear life, location, machining and maintenance historical data, thus generating relevant data for operation and preventive maintenance. Mill Setup keeps traceability of all the activities carried out in each of the phases.