SIMEC Group selects Russula to modernize rolling mill

SIMEC Group selected Russula to modernize the light structural rolling mill located in Cariacica, Espirito Santo state, Brazil. Russula will deliver the complete mechanical, electrical and engineering package for the state-of-the-art modernization. Part of a $50 million USD investment to expand the melt shop and modernize the rolling mill, this modernization will increase the production capacity of the plant to 1.3 Mtpy of crude steel and 1,05 Mtpy of hot rolled products. This mill produces 360,000 tpy of light structural rods and profiles for the Brazilian market.

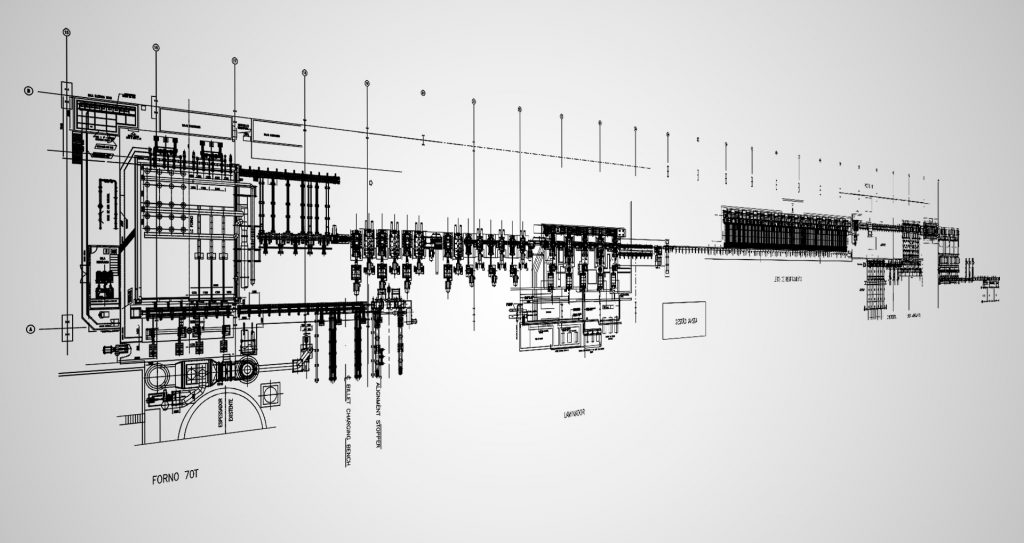

The Russula supply includes engineering, mechanical and electrical systems from the reheating furnace through the bundling area. A total of fourteen new stands will be supplied for the roughing and intermediate mills, perfectly assembled in both vertical or horizontal configuration for quicker maintenance and spare parts reduction. New crank, rotary and flying shears will help the mill meet cut tolerances and maximize throughput. The mill automation will also be modernized to a single, operating platform based on Siemens S7-1500 PLCs and WinCC.

Productivity and product quality will significantly increase after the mechanical and electrical modernization, bringing the plant up to the demanding standards of steel production today.

Equipment is expected to begin arriving on-site starting from October 2021. The commissioning is planned for the summer of 2022.