Russula celebrates thirty years of organic growth

Thirty years of acquiring new customers, developing new technologies, launching new business divisions and opening new locations all around the world.

Last march, Russula celebrated its 30th anniversary. Thirty years of business. Thirty years of organic growth. As opposed to mergers and acquisitions, the organic growth of a business builds on its own capabilities and strengths. It is a natural way of growing, expanding from within the company, using its own resources to foster a culture based on innovation and to build a reputation that customers can rely on.

Over the past thirty years Russula has grown organically; acquiring new customers, developing new technologies within a highly structured R&D department, launching new business divisions and opening new locations all around the world. Recently the company has successfully executed many important projects in Brazil, Macedonia, Mexico and the United States. The projects have grown in size and quantity in all divisions: Automation, Water Solutions, Rolling Mills, Roll Pass Design & Operations.

Automation

Automation is one of the core divisions of Russula, distinguished by over 200 separate modernization and greenfield projects for reheat furnaces, bar, section and wire rod mills. Ninety-five percent of these projects originate from repeat customers, both within the same plant or different plants within the same steel producing group.

Our clients have noticed several times that the approach of our engineers on projects is based on continuity and easy accessiblity. The engineer who configures the electrical and control system is the same engineer involved in the factory tests, installation supervision and startup support. Customers have direct access to the engineering team during every phase of the project.

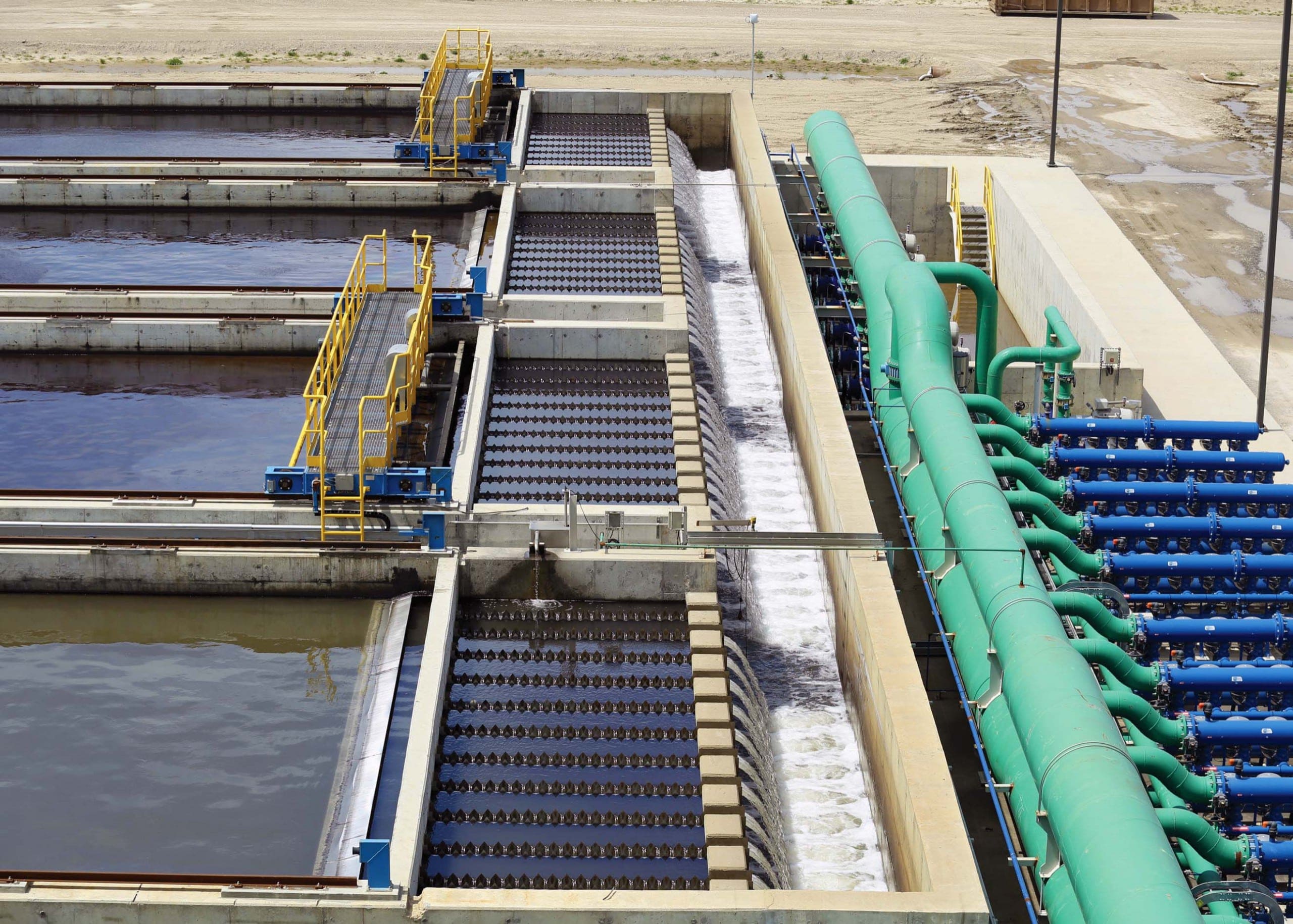

Water Solutions

In building a new rolling mill, auxiliary systems such as water treatment plants, are an area that steel producers typically don’t focus on, but they can consume a lot of maintenance resources and generate costs when the mill is in operation. Russula saw an opportunity to improve this overlooked market and collaborated in an R&D project with the University of A Coruña to develop a new water plant concept for the steel industry that focused on improving maintenance, reducing the costs of consumables and energy while minimizing the impact on the environment. In 2004, the Water Solutions Division was formed. Since then variations of this design, tailored to the requirements of each customer, have been implemented in 18 different steel plants throughout the world.

The Water Solutions Division has experienced impressive growth across steel industry sectors, starting in long product mills, then expanding into steckel mills, meltshop and finally into flat products, hot and cold rolling. Now Russula offers complete water treatment solutions in short time frames for high production steel complexes.

Rolling Mills

Over the past five years, Russula has invested in developing its Rolling Mills division. Similar to the approach taken in its Water Solutions Division, the company has challenged the status quo to improve the design and functionality of a centuries old established market, rolling mill equipment.

Steel producers today seek alternative solutions to install modern rolling mills that meet their requirements for speed, reliability and flexibility. Leveraging process knowledge gained over thirty years of experience in the steel sector, Russula has developed new technologies in wire rod applications with these criteria in mind, such as the new laying head that improves the ability to produce small diameter products at high speed. This innovative design is currently installed and operating in a 600,000 tpy greenfield combined structural steel bar and wire rod mill. After the successful implementation of that project, Russula supplied another complete 350,000 tpy mill that produces bar and sections, which permitted a European steel producer to expand its product range to medium sized merchant bars.

Roll Pass & Operations

In 2014 Russula inaugurated its second office in the US, expanding the US operations to further strengthen its presence in the long rolling market segment. The Rolling Technology Center is the home of a rolling process team that is 100% dedicated to improving operational efficiencies in long product rolling mills. The integration of this knowhow within Russula resulted in expanding the company’s service offering to develop projects in roll pass design, operational guidance and process troubleshooting.

Throughout the life of a rolling mill many things change; new grades of steel are added, product changeovers increase to fulfill smaller orders, the mill layout is reconfigured, operational practices and organizational structures change, electrical and control systems become obsolete. Years later a facility may struggle to produce in a way that is completely different from how it was originally designed or conceived, and the mill becomes inefficient.

All roll pass and operations projects are developed with close customer collaboration. Russula works closely with the full range of personnel levels inside the plant to identify and resolve its operational deficiencies. Multi-disciplinary teams are formed to ensure a 360 degree view of the mill problems from the process, mechanical and electrical points of view. Teams are purposefully kept small to provide a more personalized, flexible, service.

This new approach to improving mill efficiency has been well received by steel producers. The Roll Pass and Operations Division has had a fast market penetration and has executed more than 50 operational improvement projects in over 20 steel mills since the inauguration of the office.