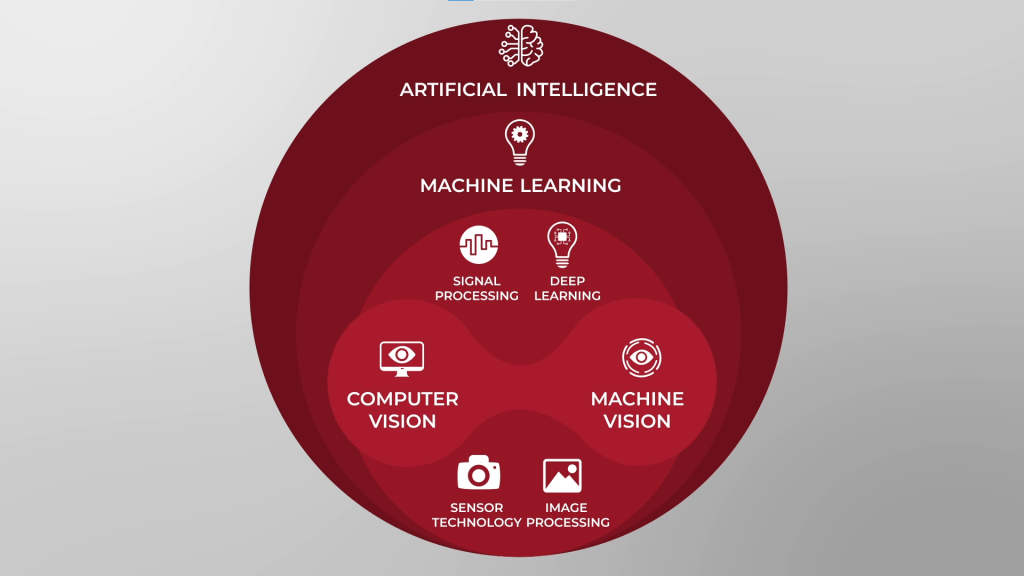

Machine vision is a subcategory of computer vision

Historically, machine vision has been a subcategory of computer vision.

The term machine vision has been widely used throughout the steel industry in recent years, perhaps more so than computer vision. Historically, the difference between the two was based on the use, hardware and application objectives.

Computer vision uses a PC based processor with sufficient processing power to extract and analyze a lot of imaging data to identify, predict and observe trends. Computer vision is focused on understanding an image in its entirety, after acquiring, processing and analyzing it.

Machine vision uses embedded controller-based processing, built to quickly analyze data and make simple, automated decisions, for quality control, inspection and guidance.

Both machine and computer vision are used today to identify and correct production line defects, inventory management, product traceability, measurement and calibration. Although machine vision is still considered a subcategory of computer vision, the lines have blurred in recent years as deep learning has given smart cameras the intelligence to analyze images in greater detail coupled with the benefits of IoT (Internet of Things) connectivity to automation equipment.

At Russula we develop computer vision applications aimed to improve rolling mill control.