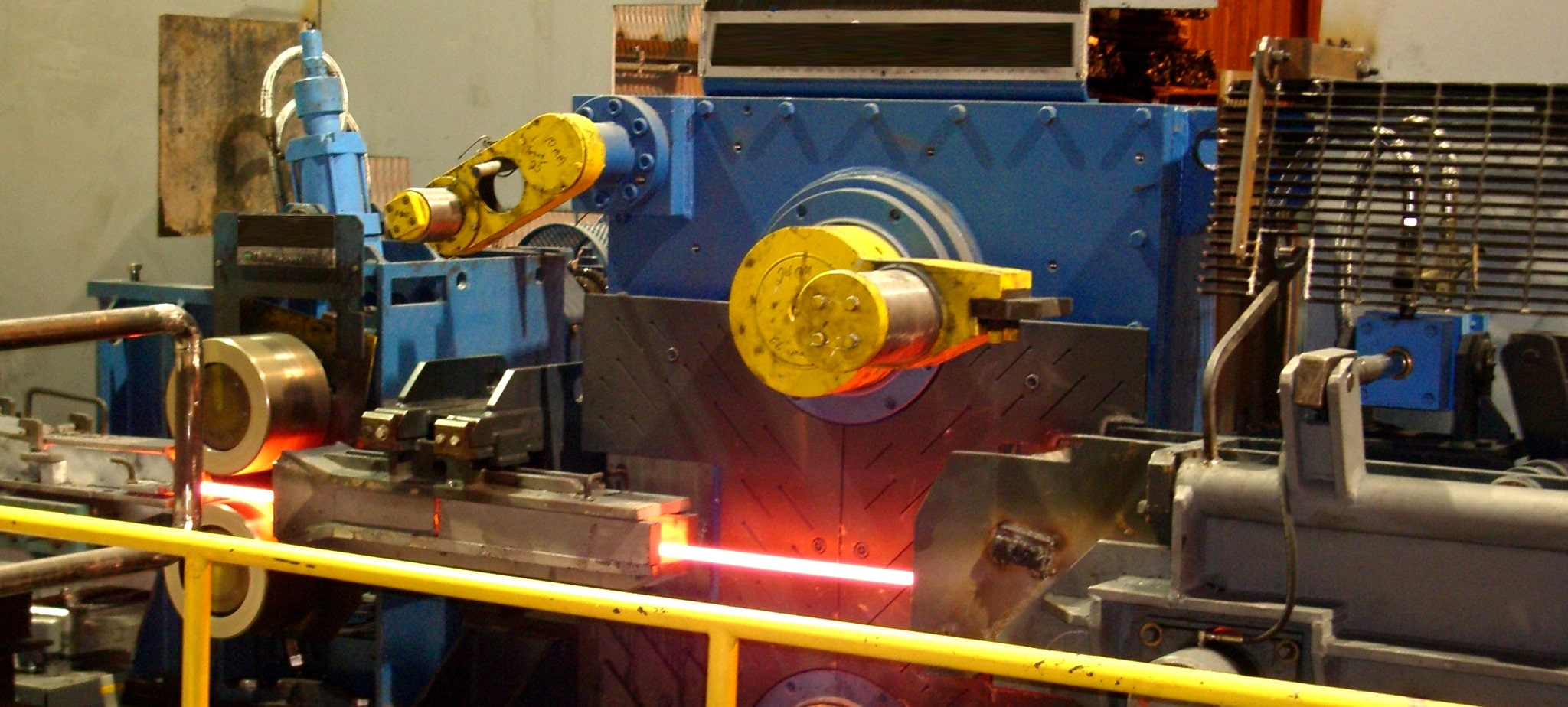

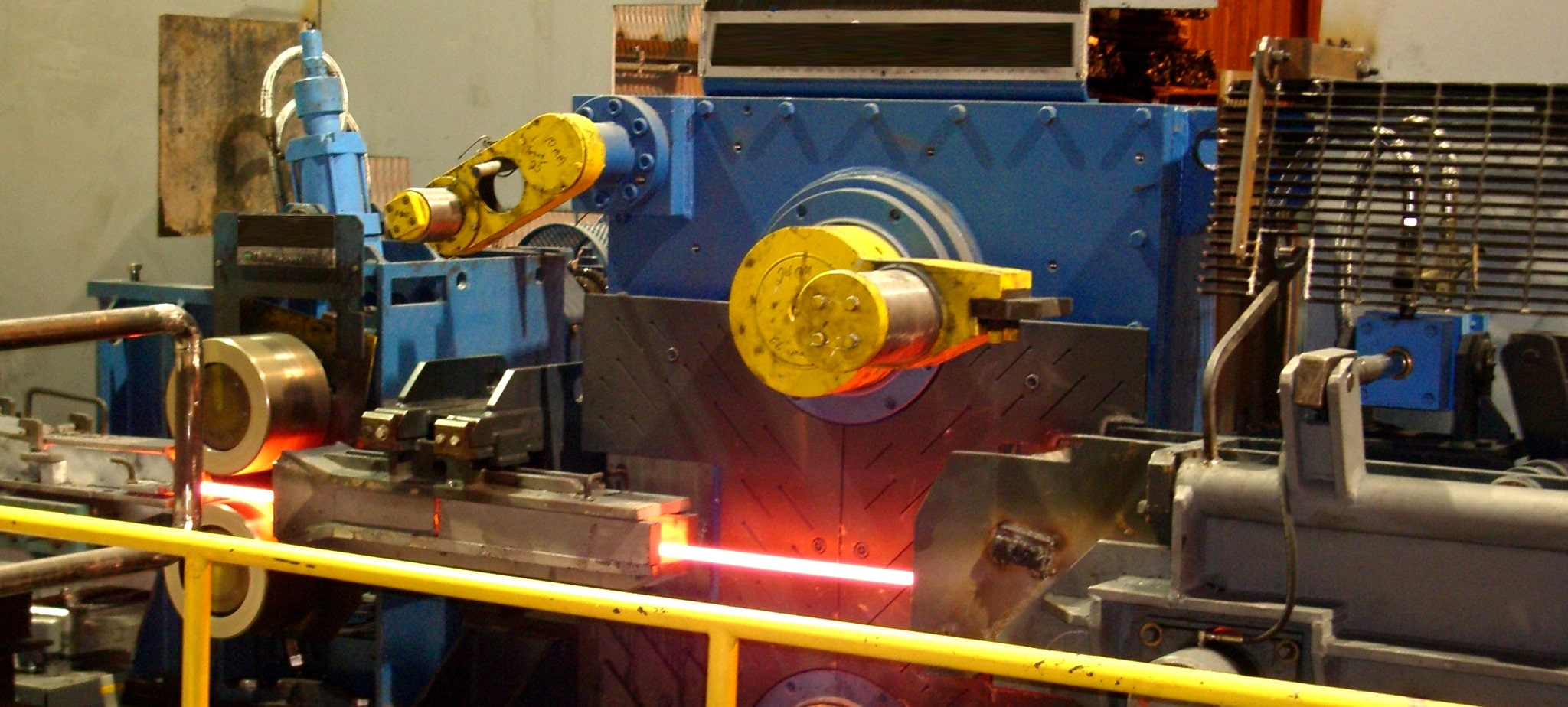

Drives and control system upgrade for merchant bar mill commissioned in just 7 days

The Gerdau plant in Wilton, Iowa, USA, contracted Russula to upgrade the merchant bar mill. The main goal of the upgrade was to replace obsolete equipment and modernize the control of the rolling mill to the same standards as other Gerdau plants. The projects consisted of a new control system, operator’s desks, HMI as well as modernizing AC and DC drives. Inside Russula's scope were project management, engineering, start-up support and training.

Project Execution

This continuous mill upgrade was a continuation of a multi-phased upgrade project:

Phase 1

Phase 2

Phase 3

Russula implemented the rolling mill control automation using standard ABB AC800M Modular Controllers. Sixteen existing ASEA mill stand drives were upgraded to fully digital control using the existing thyristors, along with complete new digital field supplies. The upgrades were pre-engineered, assembled, and tested on steel panels which were installed in the existing drive cubicles and commissioned during normal operations with no additional downtime.

"My hat's off once again for pulling through with what most deemed an unobtainable task based on too short of a time table. Your team should be commended for their expertise, desire and willingness to work the long hours necessary to bring this project to the successful state it's presently in."

Keith Elliot, Maintenance Manager

Results

The complete upgrade to the continuous mill was commissioned in just 7 days. The main benefits of the modernization were:

- New recipe system with a product dependent feature giving the plant the ability to include product dependent crop lengths, over-speed settings, cooling setup, etc.

- Self-adaptive features to compensate for roll wear.

- Reduced cycle times for data transmission which significantly improves tension/loop control and divide shear accuracy.

- Improved easiness of use of the HMI: the operator clicks on an item and receives a pop-up with the specific information instead of having to drill down through many screens.

- Easier troubleshooting with the new Analysis Displays, which gives the operator detailed information.

- Remote access services to facilitate plant production and maintenance.

- Seamless connection to the ERP system using standard Ethernet protocols.