Russula re-engineers hot strip mill at AHMSA

Altos Hornos de México (AHMSA) in Monclova contracted Russula to replace the 2Hi housings and repair the current foundation of the F2 stand. Russula provided on-site surveys, detailed engineering, technical expertise, installation preparation, construction management, installation supervision and commissioning services. The modifications occurred during the regular maintenance outage in January 2017. A multidisciplinary team of Russula experts were on-site to ensure the successful completion of the project, which improved the mill performance and operating risks.

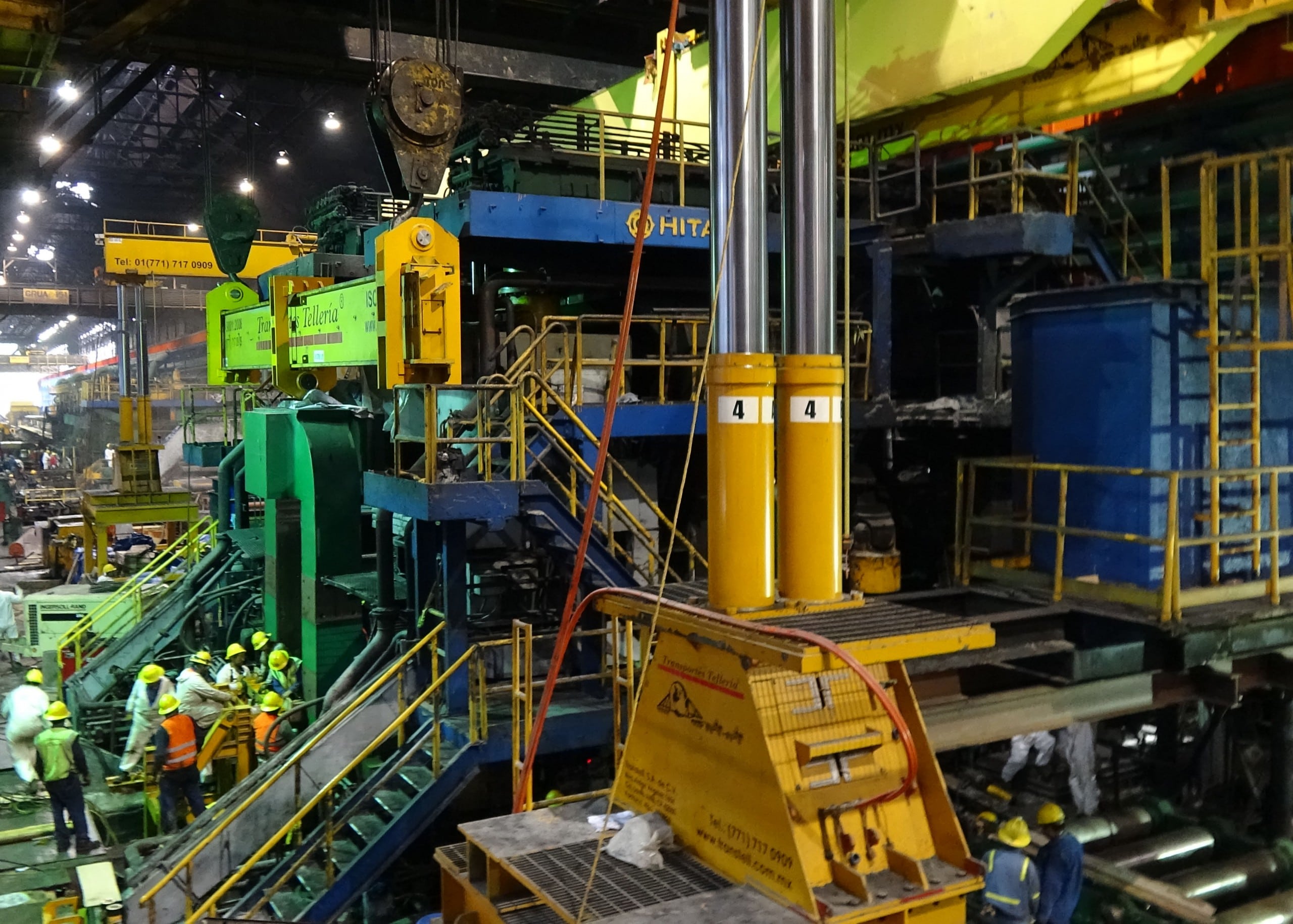

AHMSA 2 Hi hot rolling mill during the housing replacement

2 Hi hot rolling mill housing and entrance and exit roller tables replacement

In order to improve the hot strip mill reliability, the existing 2 Hi housings needed to be replaced and retrofitted with new housings. First, Russula conducted an on-site survey to identify all the steps necessary to replace the housings, planning and recourse allocation. In close collaboration with AHMSA, Russula also conducted various studies to determine the best hoisting equipment, which was a gantry crane, then defined the correct installation of the crane taking into account the weights during the maneuver, stability and load transmission.

During the shutdown, hydraulic, grease and lubrication systems, cables, railing, platforms and the edger ventilation ducts were all removed previously to prevent interfering with the extraction of the existing housings. Once the housings and bedplates were removed it was necessary to repair the sixteen 2 Hi mill anchors. After the bedplates were installed and aligned, the new housings were erected, aligning the whole assembly according to AHMSA standards.

Russula also assisted in the replacement of the entry and exit roller tables of the 2 Hi mill as well as the exit table of the 2nd section of Furnace 4. This included repairing the foundation and disassembly and replacement of the turrets, guides, electrical motors and transmissions.

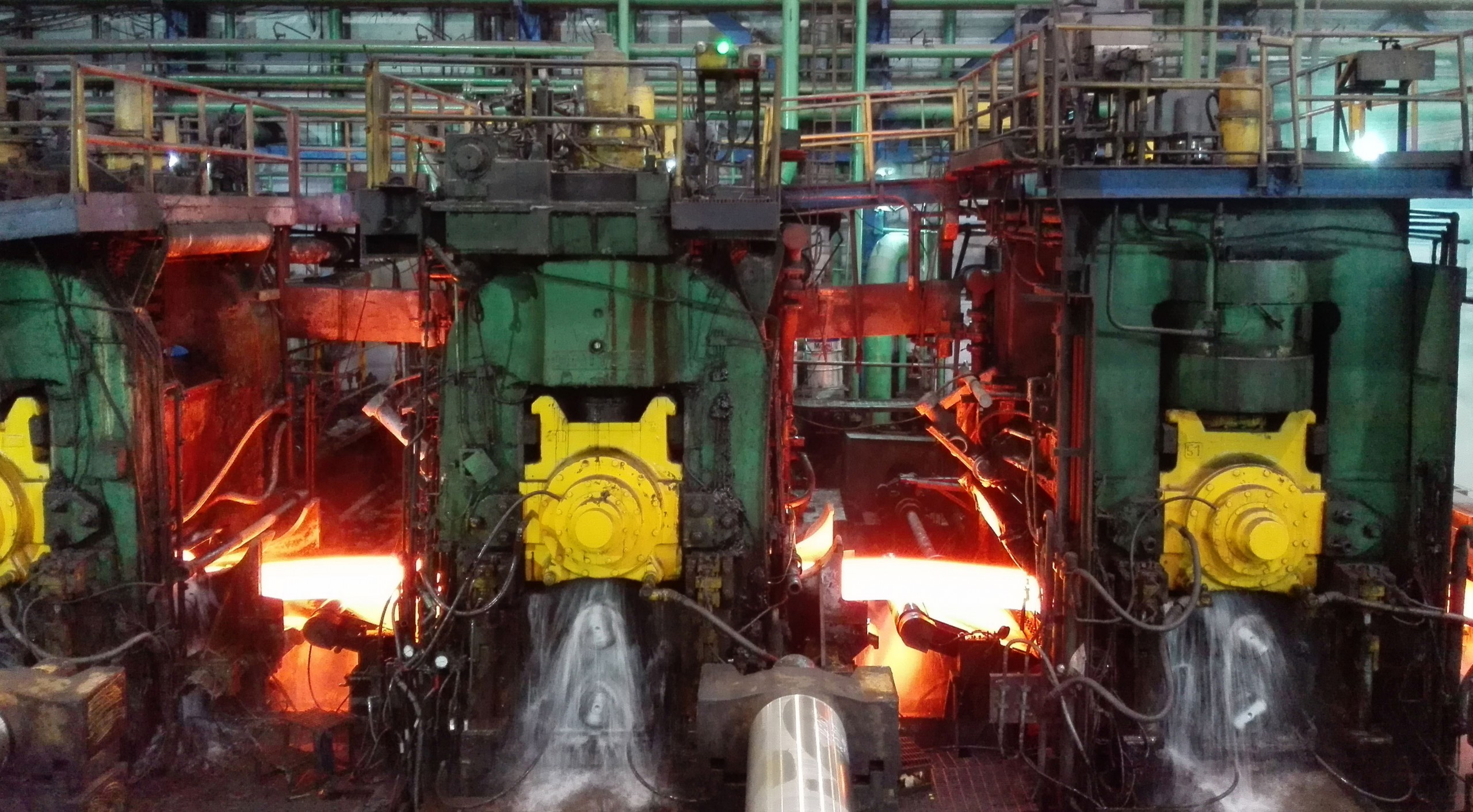

Finishing mill area | F2 stand foundation repair

After conducting an extensive on-site analysis, it was determined that the existing foundation for the F2 finishing mill stand was structurally insufficient and needed to be repaired. As part of a multi-disciplined project execution team, Russula provided basic and detailed mechanical, civil, structural and electrical engineering, procurement, and construction management services to remove and rebuild the existing foundation and reinstall the F2 finishing stand. While the detailed engineering work was carried out in the Russula headquarters in A Coruña, Spain, a team of Russula engineers were on-site from the start of the project to conduct the field survey and identify all the equipment that would be affected by the modifications.

Assembly and alignment of the bedplates in its final position

Improvements implemented in January 2017

The Russula project team was highly integrated with the AHMSA organization, aligned to the management objectives and committed to a speedy delivery of the improvements. Since the hot strip mill at AHMSA was producing during the preinstallation phase of the new housings, this presented safety and scheduling challenges.

A team of Russula experts, specialized in civil, mechanical and electrical engineering was on-site to supervise the replacement of the new 2 Hi housings, the entry and exit roller tables and the F2 stand foundation. All the modifications were conducted during the 28-day-long regular maintenance shutdown in January, 2017. Russula supported the cold and hot commissioning.

Successful startup in March 2017

Russula is also responsible for the basic civil engineering, detailed mechanical and electrical engineering,

start-up supervision and training. The mechanical and electrical equipment was delivered to the plant in November 2016. The hot strip mill was successfully commissioned in March 2017 and is back in operation.

Successful March 2017 startup