Russula supplies several optical alignment systems to steel plants

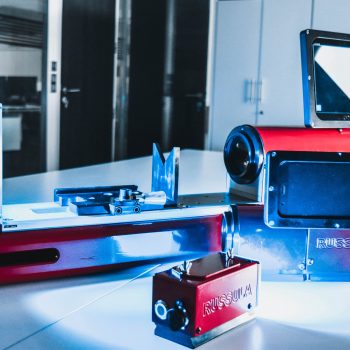

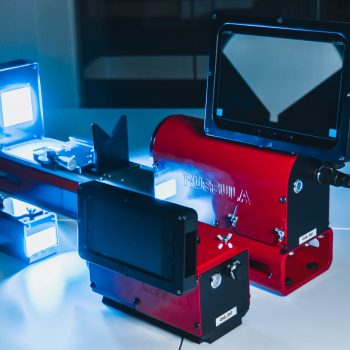

Russula has supplied several optical alignment systems to steel plants on both sides of the Atlantic Ocean. Developed and prototyped in house by our own engineers, the novel system speeds up the time to set and align finishing block roller guides, reducing downtime and improving steel quality.

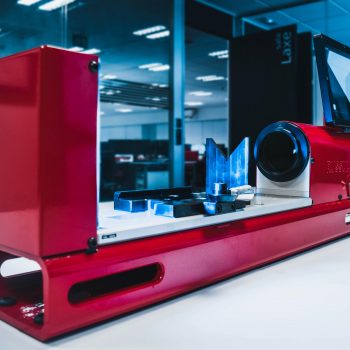

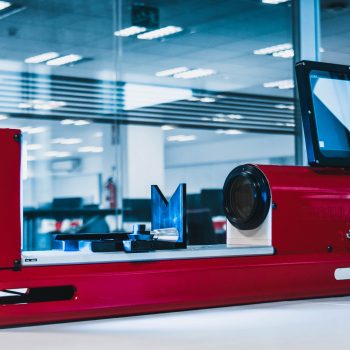

Typical optical alignment systems (OAS) are adjusted by eye using shadow projection systems on a bench optic. Shadow adjustment methods require that the optical components are regularly calibrated and carry the disadvantage of human error. Russula's design is based on artificial vision. Employing telecentric lenses, high resolution cameras and Russula’s own artificial vision algorithms, operators can now adjust the block guides and corresponding mounting bases to perfection, with full digital feedback.

The Russula OAS system comes in two models: a bench optic for the setting the roller guides, and a portable optic for aligning the guide saddles to the mill rolls. Both models are rugged, ideal for rolling mill environments. Rechargeable batteries mean hours of operation, unplugged.

The Russula OAS is user-friendly. Changes in the roll pas design or setup can easily be updated through the profile target database. Navigation is intuitive from the OAS screens, a laptop or smartphone. Guide and mounting base adjustments take only a matter of minutes.