Novelis aluminum slitter electrical and automation upgrade

Russula provided the complete electrical and automation equipment to upgrade the slitter. The main objective was to replace legacy equipment with a modern control system that improved productivity, equipment reliability and process stability.

The scope of supply included:

Improve production reliability through data gathering and analysis

Russula provided various IBA data acquisition tools. Data gathering and analysis is paramount to ensuring greater reliability and security for the production process.

Condition monitoring for motor vibration predictive maintenance

Condition monitoring is an important part of any predictive maintenance program. By monitoring a key parameter of machinery, the maintenance team is informed of any significant changes, which could be indicative of a developing fault. As part of the electrics and automation upgrade of slitter no. 2, the Novelis plant monitors and analyzes motor and machine vibration.

Russula implemented the Iba InSpectra tool which collects and analyzes vibration data from sensors mounted on the motors. This tool was fully integrated with the automation system and helps the maintenance department perform preventive maintenance by using trend graphs, alerts and alarms.

Typical predictive maintenance condition monitoring screen

Cameras synchronize images and process signals

The slitter machine has six, 36 fps AXIS IP cameras installed in strategic locations along the process. The images from the cameras were synchronized with the process signals. With this system event-triggered process sequences of special interest “video triggers” can be recorded separately and stored in a protected area of the hard disk, so that video recordings are not replaced by continuous recording and important process events are stored for longer data retention, available later for playback and further analysis.

The precise linking of measured data and visual information provides high quality analysis to process operations. Operators are able to look at visible process events in the process and the corresponding historical measured data at the same time on one screen. Tasks such as troubleshooting and process analysis, starting a new campaign, training and operating procedures documentation are easier with this system in place. The operators have an overview of the entire production line which allows production to respond and resolve problems quickly.

A typical camera capture screen

Virtualized environment

Russula provided a virtualized environment to Novelis that integrates the process servers and workstations. Six iba capture cameras and six thin client workstations were integrated into the new virtualized environment.

Electrical Signature Analysis monitors motor condition

The Novelis Pindamonhangaba plant uses Electrical Signature Analysis (ESA), a system comprised of both hardware and software, to monitor the condition of its electrical motors. ESA is a technique for analyzing motors, generators, alternators, transformers, and other electric equipment. The technology can test operating electrical equipment and identify several mechanical and electrical problems; for example, ESA traces can analyze the driven load, the power supply, and perform inrush testing on motors. As a preventive maintenance tool, ESA can be used for either single or periodic testing to track equipment performance. It is noninvasive, online and remote. In the case of the Novelis slitter, ESA is used to diagnose motor and tranmission system failures.

Diagnostic Failures through Electrical Signal Analysis:

Novelis uses ESA to monitor electrical motor condition

Successful startup November 2017

The electrical and control system performance test was successfully conducted at the end of August 2017 in Russula’s workshop in A Coruña, Spain. During that time Russula engineers provided extensive guidance and hand-on training with respect to the multidrives, Siemens Sinamics and WinCC TIA. Slitter no. 2 was successfully upgraded during a shutdown from November 20th to December 1st, 2017. The control uprade helped Novelis leverage the latest control technology to produce excellent quality, tightly wound, straight-sided slit coils.

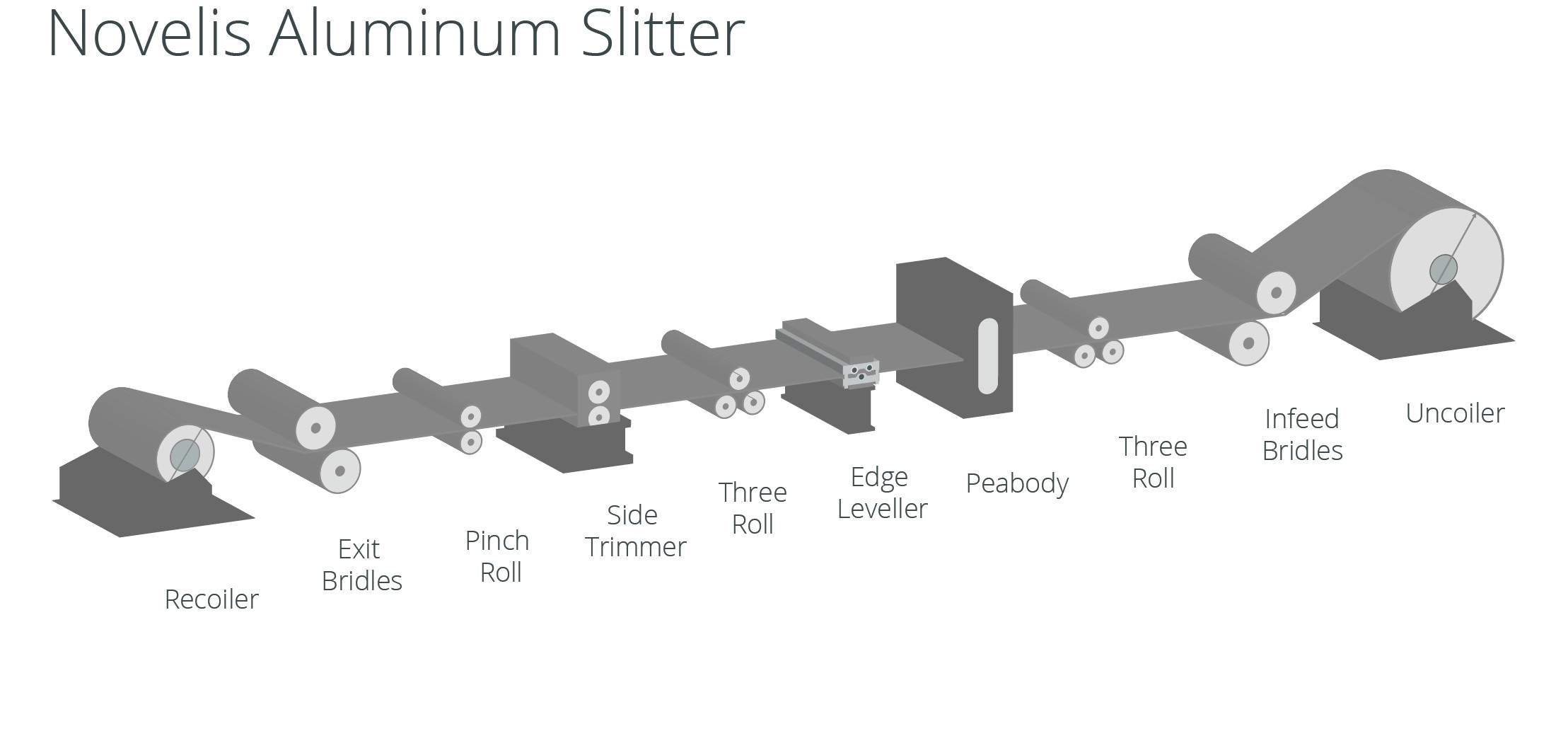

General schematic of slitter no. 2 aluminum finishing mill at Novelis in Pindamonhangaba, São Paulo, Brazil

General schematic of slitter no. 2 aluminum finishing mill at Novelis in Pindamonhangaba, São Paulo, Brazil