Light structural mill electrical and automaation modernization

The SIMEC Group selected Russula to modernize its light rolling mill in Cariacica, in the state of Espirito Santo, Brazil. Russula will supply the complete mechanical, electrical, and technical package for the state-of-the-art retrofit. This upgrade is part of a $50 million investment to expand the smelter and modernize the rolling mill and will increase the mill's production capacity to 1.3 Mt of crude steel and 1.05 Mt of hot-rolled products by year. This plant annually produces 360,000 tons of bars and light structural profiles for the Brazilian market.

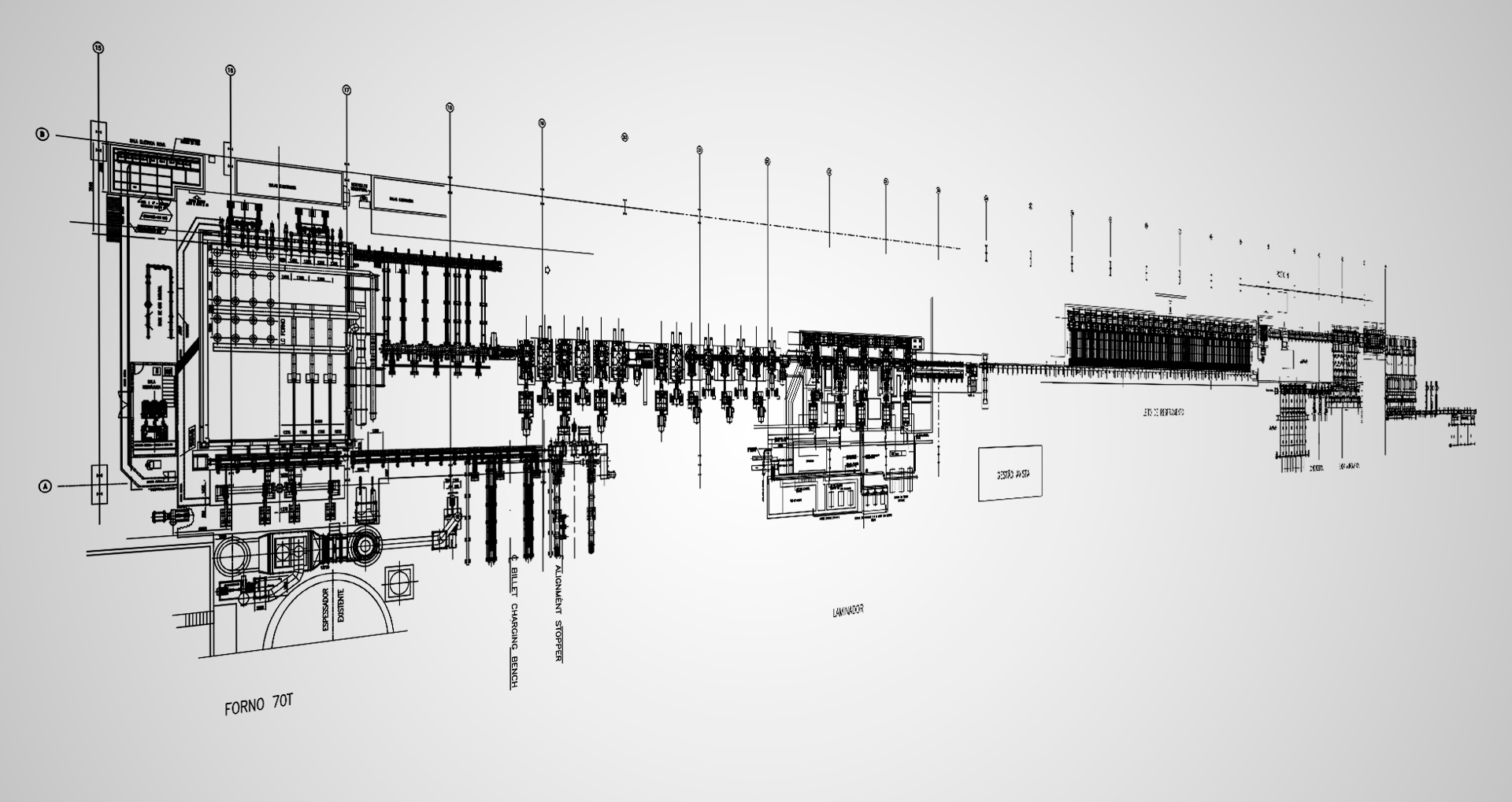

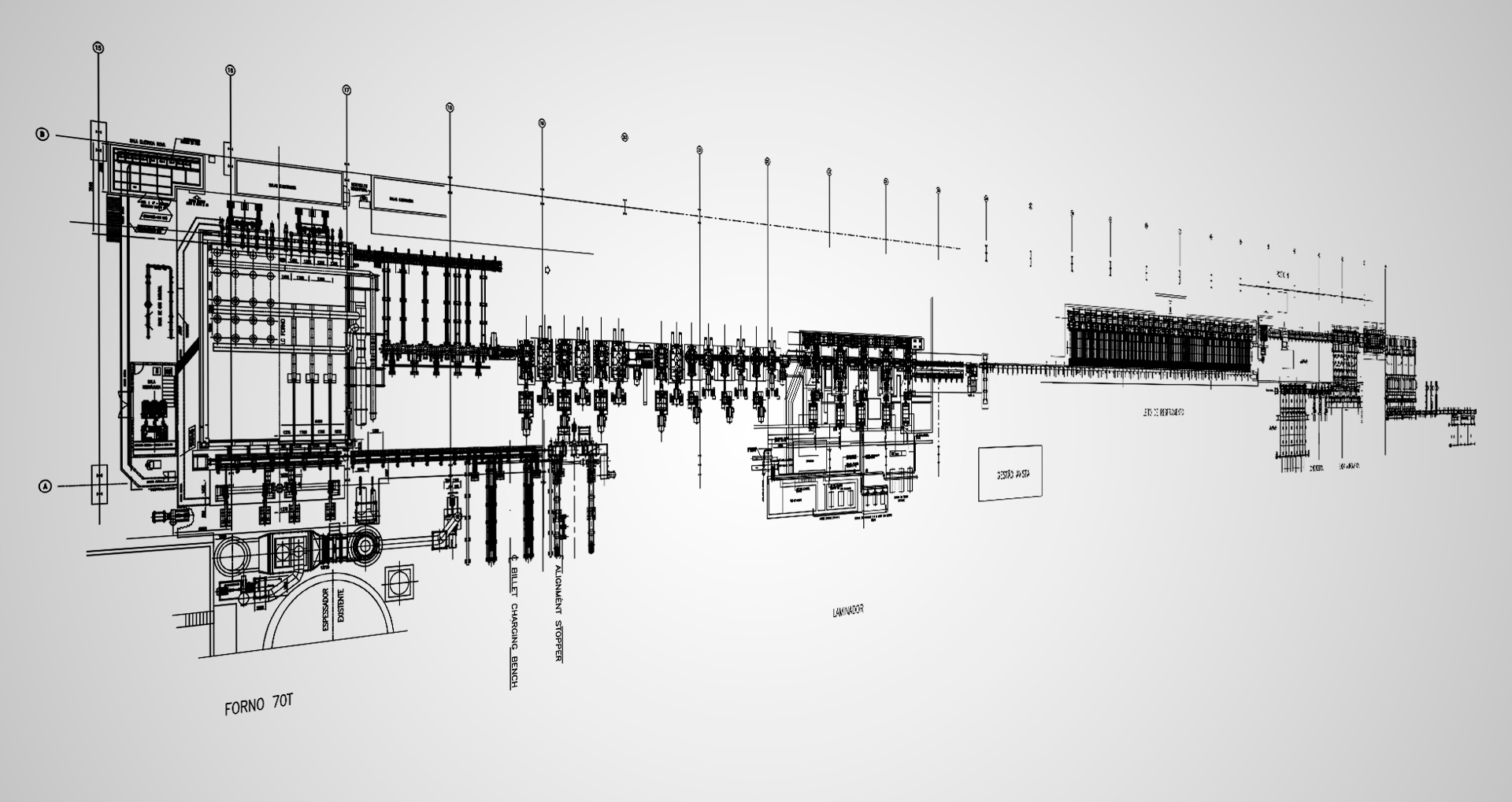

Russula's offering includes engineering, mechanical and electrical systems from the reheat furnace to the packaging area. A total of fourteen new roughing and intermediate mill stands are supplied, neatly assembled in vertical or horizontal configuration to speed up maintenance and reduce replacement parts. The new crank, rotary, and flying shears will help the plant meet cutting tolerances and maximize throughput. Factory automation will also be upgraded to a single operating platform based on Siemens' S7-1500 PLC and WinCC.

Productivity and product quality will increase significantly following the mechanical and electrical upgrades, allowing the plant to meet today's stringent standards for steel production.