İsdemir grants Russula final acceptance for water boxes

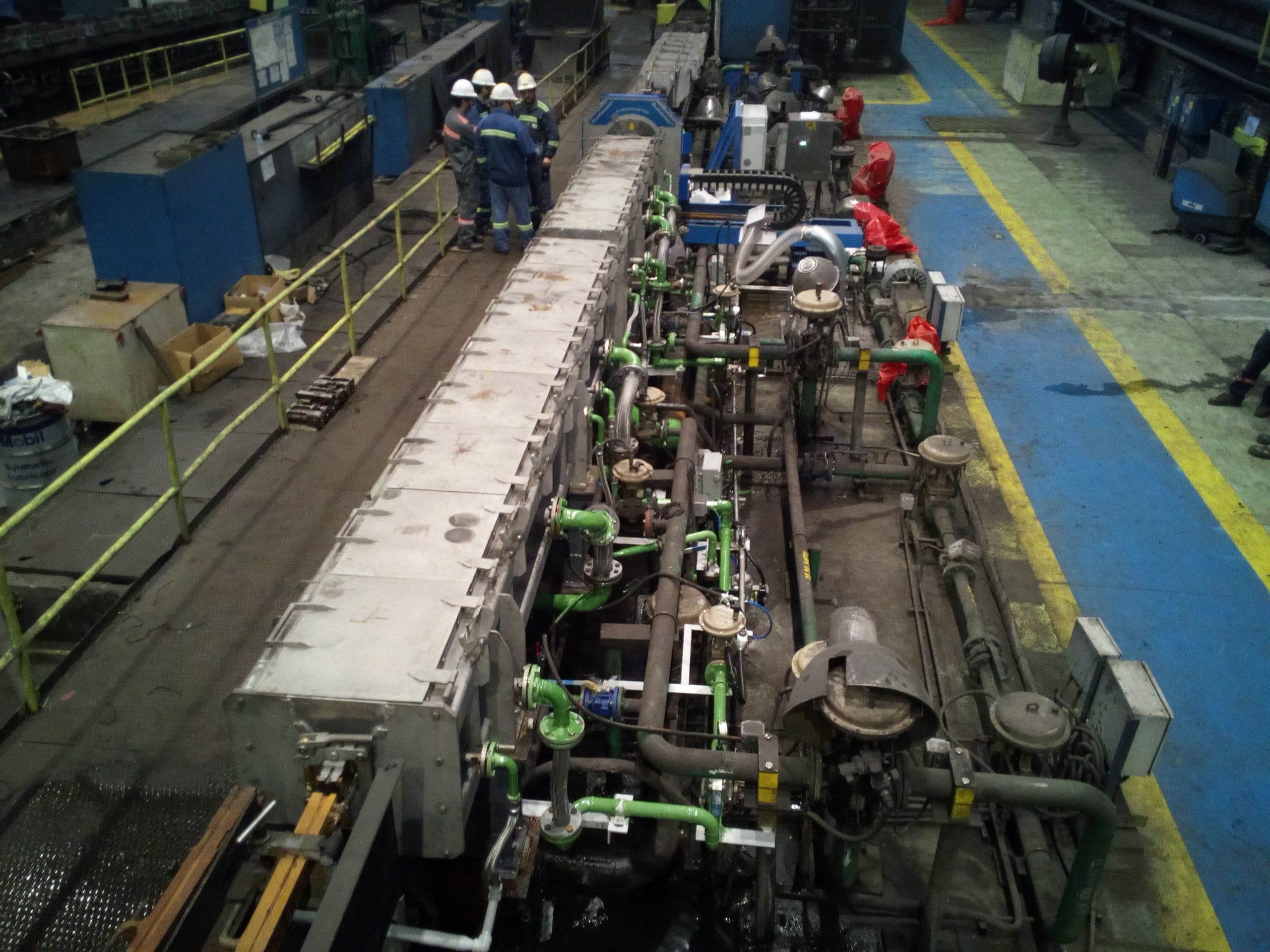

İsdemir chose Russula to install two of the four water boxes of the wire rod mill. Russula was responsible for the engineering, installation advisement, commissioning support and spare parts supply.

After the successful upgrade of the automation system and drives of the two-line wire rod mill in 2015, İsdemir chose Russula to install two of the four water boxes of the same mill. Russula was responsible for the engineering, installation advisement, commissioning support and spare parts supply. All detail piping, engineering and installation were executed by Erdemir Mühendislik.

In February 2018, the equipment was shipped to the plant and on March 8th İsdemir stopped production to install the water boxes. Shortly after, on March 23rd, the installation was completed and the commissioning successfully took place.

Not only was the homogeneity of the bar increased, but also the water flow rates were reduced by more than half compared to the existing line. The total flow needed to reduce the bar’s temperature to 230ºC in the other cooling line was 124 m3/h. In comparison, the line with the new water boxes only required 70 m3/h to reduce the bar’s temperature to 230 ºC.

On June 8th İsdemir granted Russula final acceptance for the water boxes. Russula would like to thank İsdemir for their trust and excellent collaboration.

About İsdemir

İsdemir, owned by OYAK Mining Metallurgy Group, is Turkey’s only integrated iron and steel plant that produces both long and flat steel. It is located in İskenderun, in the province of Hatay, on the Mediterranean coast, in the south of Turkey.