Gerdau Whitby orders new combined dividing shear from Russula

Gerdau Long Steel North America, located in Whitby, Ontario, Canada has placed an order for a new combined dividing shear. The Gerdau Whitby mill produces angles, channels, rounds, square reinforcing and flat bars.

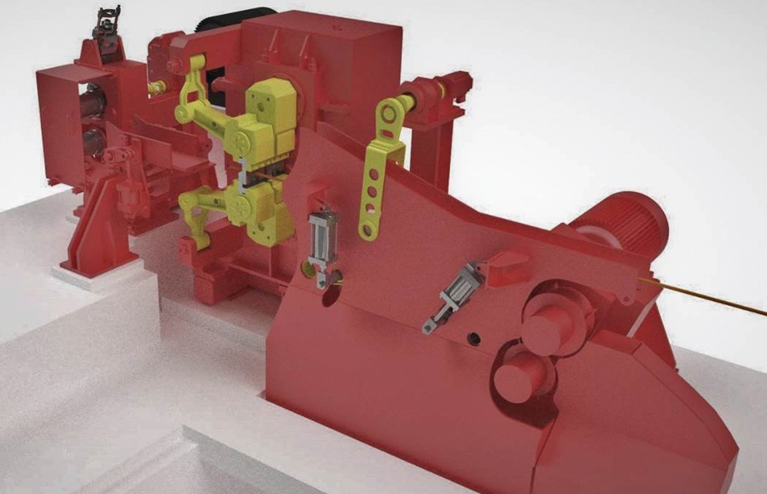

Within the project scope, Russula will supply a new pinch roll, a divide shear, servo actuated diverter and a chopping shear. The mechanical and electrical equipment including the motion controller, drives, servos and new motors is also included within the scope of supply. Russula is responsible for the engineering, installation supervision, commissioning and production support.

The new 40-ton combined shear is multi-functional with both crank and flying modes. The shear is movable. In order to switch between the crank and flying mode the complete shear assembly can be moved hydraulically. This feature reduces the switching time to a few seconds and avoids the laborious task of coupling and uncoupling the shear cutting arms.

The new combined dividing shear is scheduled to be in full operation by the summer of 2019. Taking advantage of our extensive knowledge of the steel process and experience in mill revamping, Russula specialists are equipped to develop equipment that will improve productivity and mill performance.

Russula has a long-standing relationship with the Gerdau Whitby plant over the past thirteen years. In 2004, Russula upgraded the bar mill. The upgraded resulted in an 8% production output increase.

Recently, Russula supplied all the electrical equipment and control software necessary to upgrade the 120 tons/hr reheat furnace, such that the mill complied with international safety standards and improved plant safety and reliability.