Gerdau Petersburg furnace drives upgrade

Gerdau, together with Russula, upgraded the reheat furnace drives of the structural steel mill, in Petersburg, Virginia, USA. The purpose of the upgrade was to replace obsolete equipment with modern AC drives that removed bottlenecks and improved plant performance.

Scope of Supply

The existing AC multidrive, controlling the stock, coming either from the cold or caster lines or the charging and discharging furnace areas, was replaced with the ABB ACS880-X04 multidrive series with Regenerative Rectifier Units (RRU). Besides the electrical equipment, Russula also provided engineering services and spare parts.

Regenerative Rectifier Units

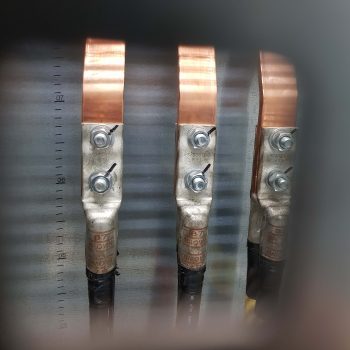

The RRU is a fully regenerative rectifier consisting of one or more rectifier modules and an L-filter. Each module consists of six IGBT components and six diodes connected in anti-parallel. In motoring mode, current flows from an AC supply through the diodes to a DC bus. In regenerating mode, current flows from the DC bus through the IGBTs to the supply network. The IGBTs of the regenerative rectifier unit are switched, conducting only once during each network voltage half-cycle, which is comparable to a 6-pulse diode supply unit. This reduces switching losses and allows higher power ratings for the power module. Because the IGBTs can be switched off at any time, RRU – unlike a thyristor bridge – is reliable also during supply network failures when in regenerating mode. It is a more cost-efficient solution for regenerative supply.

Results

The AC drives were assembled in the Russula workshop at the end of 2018. The factory acceptance test occurred in January, 2020 and the startup was in late February of the same year.