Chusovoy Metallurgical Works signs a contract for the supply of new equipment for the rolling mill expansion project

Chusovoy Metallurgical Works (JSC CMW, Perm Region, part of OMK) awards Russula (A, Coruña, Spain) a contract for the supply of the water treatment plant equipment as part of an expansion project to current rolling mill production.

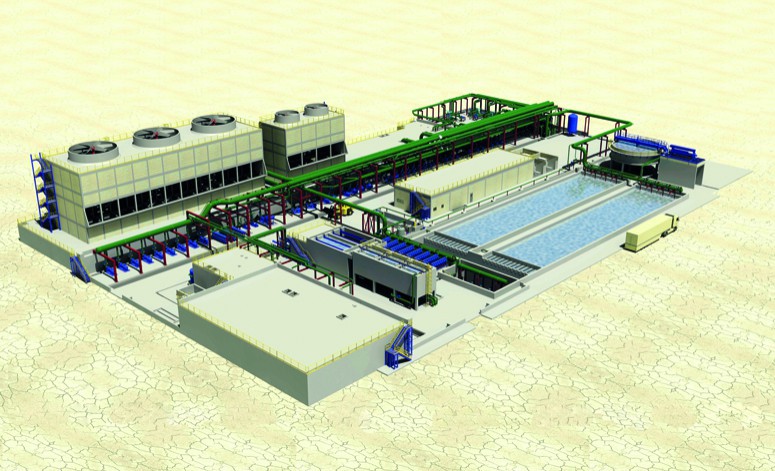

The system of closed water circuits will provide the required water treatment necessary for cooling the furnace, hydraulic and other modern equipment of the new rolling mill, which will be installed at CMW. The water treatment plant equipment investment is 260 million rubles. Equipment supply is scheduled to be delivered in the 4th quarter of 2020.

The total capacity of the water treatment plant will be 1,500 m 3/hr. Special technology allows the waste water to be treated and reused again in the cooling system, thus eliminating the negative impact on the ecosystem.

“Technological solutions for the recycled water treatment and cooling extend the life of the new rolling mill equipment while fully complying with environmental standards. This will ensure the reliability of the new mill and will provide CMW´s spring production lines with the highest quality product.” said Dmitry Shulyatiev, project manager for the rolling mill production expansion at CMW.

The water treatment system is completely automated and will be controlled by one operator. The operator will control the parameters of the process, conduct the water treatment process and inspect equipment. The system includes horizontal decanting basins, ring filters and strainers, cooling towers for the water cooling, skimmers for oil removing, thickener and decanter for sludge dewatering, as well as dosing stations for chemical treatment.

About OMK rolling mill expansion project

OMK is installing a new rolling mill to expand production at the Chusovoy Metallurgical Works, which includes a modern bar and light section mill, water treatment plant and roll shop. OMK’s investment in the project is 3.6 billion rubles.

The new mill will produce more than 200,000 tons/yr of rolled steel. With this project, CMW will be able to roll the highest quality steel for its automobile spring lines, produce new types of steel in high demand on the market and significantly improve the working conditions of its employees. The installation of the mill equipment is scheduled for the end of 2020. Production is foreseen to begin in 2022.