ArcelorMittal Acindar mejora la electricidad y la automatización

In January 2020, the bar mill drives and first phase of the wire rod mill were upgraded at the ArcelorMittal steel plant in Villa Constitución, Argentina. The commissioning took place during a maintenance shutdown where the Acindar and Russula team were on-site to ensure that the two mills successfully returned to production as scheduled. The goal of the upgrades was to replace legacy electrical and automation equipment that had become obsolete with first-line control and hardware to improve rolling reliability and performance.

Scope of Supply

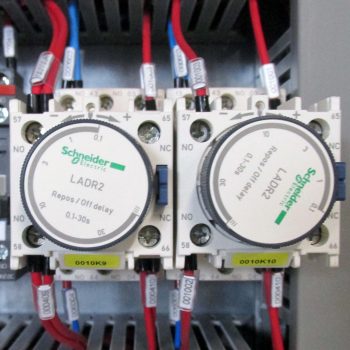

New ABB DCS880 drives were supplied to replace the existing drives of the bar mill. Electrical engineering, integration of the drives into the existing control system, supervision installation and production support were also included within the scope of supply.

The wire rod mill underwent a complete automation and electrical revamp, implemented in two phases. First, the DCS500 drives were upgraded to DCS800 for the transfers cars, Kocks block, crop and chopping shears, pinch roll and laying head. The existing auxiliary equipment control, ABB AC410 PLC, was replaced with an AC800M model, and the two roughing shears now have new Simotion positioning logic.

The second phase entailed upgrading the existing wire rod mill ABB AC450 controllers and IO signal cards to an AC800M model and its corresponding cards were mounted in new cabinets. New Simotion positioning was supplied for all pending devices. Wonderware Intouch was substituted with a redundant server architecture HMI, cluster type, with Wonderware Archestra. All HMI and engineering stations were virtualized on these servers using the ThinClient interface. ThinClient stations replaced all standard PC computers.

Results

As a system integrator The successful commissioning of both upgrades occurred in January, 2020 during a maintenance shutdown. Russula was pleased to implement this important project together with the ArcelorMittal Acindar team.